Products

Production

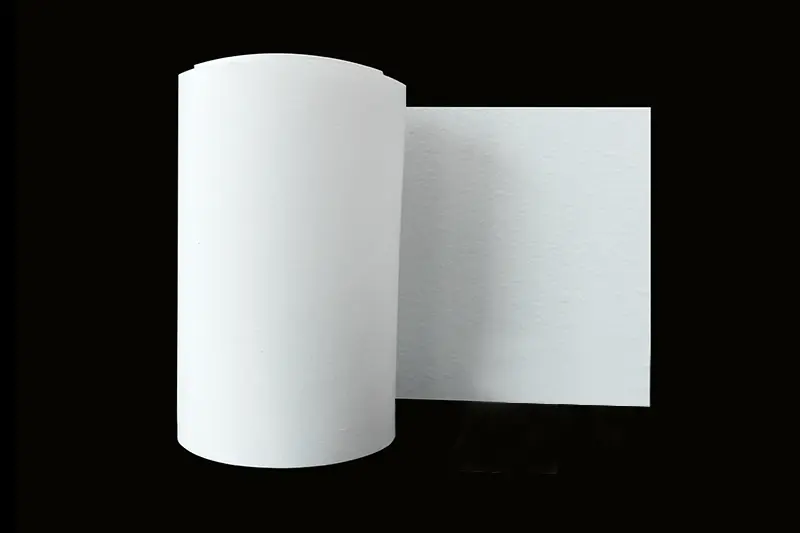

Microporous Board

Keywords:

Microporous Board

Classification:

- Details

-

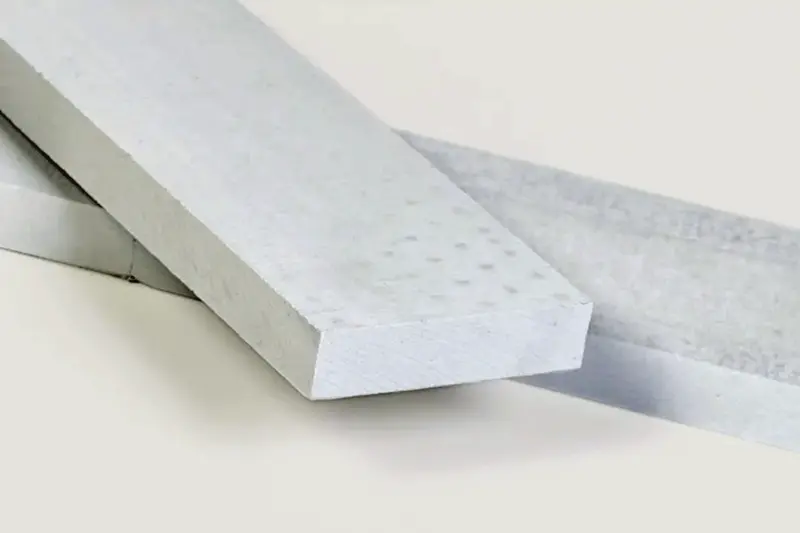

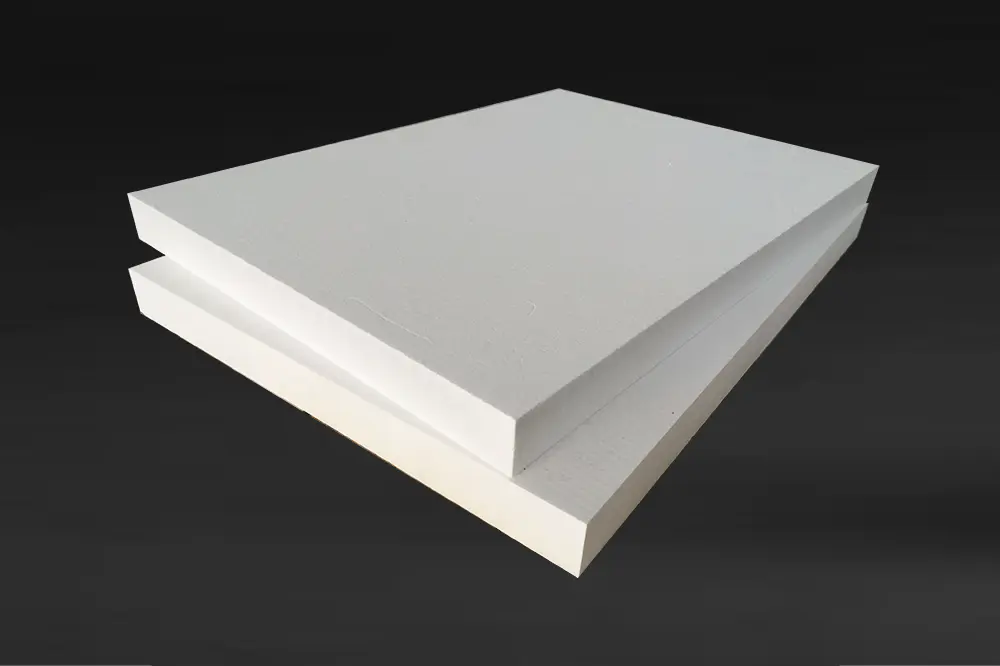

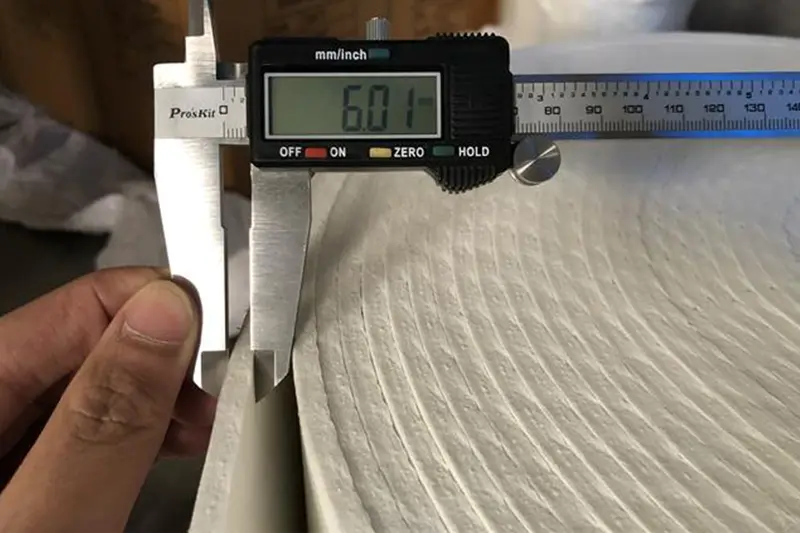

The main components of the microporous board is nano silicon dioxide and silicon carbide. It is a new type of heat insulation material obtained after a series of physical and chemical reactions, consisting of silicon dioxide particles with diameters of tens of nanometers, and infrared sunscreens and fibers. It is also called nano-board, nano-insulation board, nano-insulation board, thermal insulation material, nano-composite insulation board, nano-aerogel, nano-microporous thermal insulation material, etc.

Features

1. Have a very low coefficient of thermal conductivity, thermal insulation performance is the traditional insulation material (ceramic fiber, calcium silicate, rock wool, etc.) for 5 to 7 times.

2. The coefficient of thermal conductivity changing with temperature rising modestly, is ideal for high temperature heat insulation material.

3. Heat-resistant up to 1050 ℃.

4. Grade is A1 incombustible material, good thermal stability, less heat, heat shock, long service life.

Applications

1. Rigid high temperature gaskets and seals

2. Fire protection systems

3. Domestic boiler heat exchanger linings

4. Heat shields for personnel protection

5. Trough/distribution linings for conveying aluminium

Quality Control

SHANDONG HIKING INTERNATIONAL COMMERCE GROUP CO.LTD Founded in 2002. our company is located in Qingdao city, Shandong Province.It has developed into one of the largest manufacturers of refractory fibers in Asian areas through many years struggle. At present, our factory has more than 600 employees with total areas of nearly 50.000 ㎡. We can produce all kinds of Ceramic Fiber Products such as Ceramic Fiber Blanket, Ceramic Fiber Board, Ceramic Fiber Paper, Ceramic Fiber Bulk, Ceramic Fiber Module etc. with annual capacity of more than 8 thousand tons.

Packing & Shipping

In the recent years’ development,we are owning eighteen of ceramic fiber blanket production linese sixteen lines are spun ceramic fiber type,two is blown ceramic fiber type;one process vacuum form ceramic fiber products line;two ceramic fiber module lines;one ceramic fiber paper line. At the same time, our factory has been keeping touch with the most authoritative technical research centers for many years, we are improving ourselves in production all the time, such as the new products’creation, manufacturing design , after-sale service.

Relying on consummate manufacturing technology and abundant technical power which is the guarantee of product quality, our company has passed 9001:2000 Quality Management System Attestation in advanced the other company.

Our products are sold to many foreign countries suchas :KOREA,JAPAN,USA,SAUDIARABIA, UK, GERMANY, TURKEY,PK,MALAYSIA,DUBAI,CHILE,VIETNAM and SWITERLAND etc.we also had continuously developed new products and strengthened after-sales service in metallurgy, electric power, petroleum, chemical industry as well as many other fields, greatly meeting market demand.

More products

Refractory Material

Alumina fiber

-

1600℃ (3000℉) Alumina Fiber Board

1600℃ (3000℉) Alumina fiber board is made of alumina fiber bulk, compressed together with organic and inorganic adhesives by wet vacuum forming process.

-

1600℃ (3000℉) Alumina Fiber Paper

1600℃ (3000℉) Alumina fiber Paper is mainly made of polycrystalline alumina fiber and binder, with advanced flame retardance property, heat-insulating property, electrical insulation property, High & Low temperature resistance property and ageing resistance property.

-

1600℃ (3000℉) Alumina Fiber Blanket

1600℃ (3000℉) Alumina fiber needling blanket is processed by chemical "Sol-Gel" into spinning solution containing aluminum oxide silicon, then special processed into precursor fiber bulk, after carding, flattening, needling, high temp annealing.

-

Microporous Board

It is a new type of heat insulation material obtained after a series of physical and chemical reactions, consisting of silicon dioxide particles with diameters of tens of nanometers, and infrared sunscreens and fibers.

Bio-soluble Fiber

-

Bio Soluble Fiber Board

Bio Soluble fiber board is manufactured in a wet forming process using Bio-Soluble fiber bulk and binders. Bio-soluble fiber board is designed for insulation applications experiencing vibration, mechanical stress and erosive forces.

-

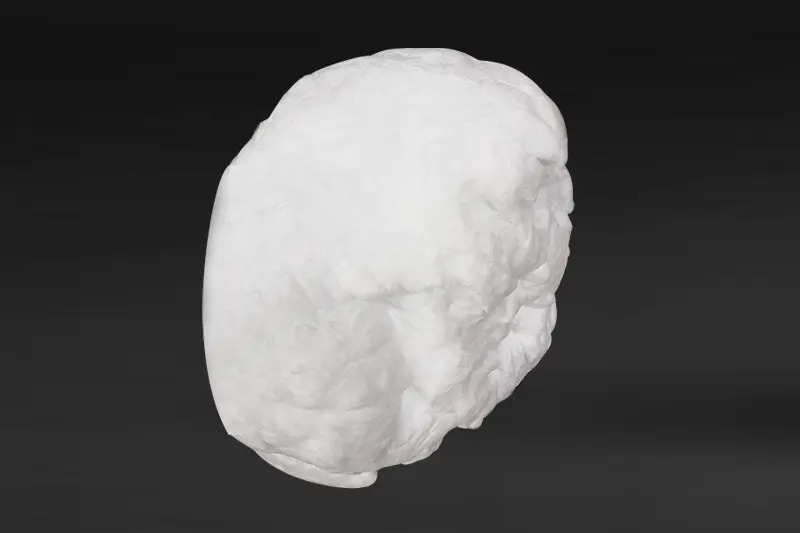

Bio-Soluble Fiber Bulk

CCFR® Bio-Soluble Fiber Bulk is a new develop at the basic of the traditional ceramic fiber, the main components is MgO, CaO, with integrated fire resistance, heat separation and thermal insulation functions.

-

Bio-soluble Fiber Blanket

CCFR® Bio-soluble Fiber Blanket is high strength, needled insulating blanket that is made from Soluble ceramic fiber bulk. The combination of spinning and needling operation produce tough,resilient and strong blankets,which have superior thermal and mechanical properties.

-

Bio-Soluble Fiber Paper

CCFR® Bio-soluble Fiber Paper is a new develop at the basic of the traditional ceramic fiber,It is a type of fiber paper made from MgO, CaO, and a small amount of organic binder.

Calcium Silicate Board

-

High Density Calcium Silicate Insulation Board

With density range 750--900kgs/m3 ,high density calcium silicate insulation board is developed for the non-ferrous industry used for feeding ,casting and molding of molten aluminum and other non-ferrous metals, also can be used for clamping fixture of glass industry.

-

Calcium Silicate Board

The main constituents of 1000℃ calcium silicate insulation board is Xonotlite and reinforced glass fibre,no asbestos. It is a kind of high efficient energy-saving material with temperature limited 1050 cent-degree.

Ceramic Fiber

-

Expanded Graphite Ceramic Fiber Paper

Expanded graphite ceramic fiber paper is processed with high-quality ceramic fiber cotton and expanded graphite, which is after beating, mixing, matching binders, molding and drying, cutter, packaging and other craft production into high-quality expanded graphite fiber paper.

-

Ceramic Fiber Board

Ceramic Fiber board is manufactured in a wet forming process using Ceramic Fiber bulk and binders. Ceramic Fiber board is designed for insulation applications experiencing vibration, mechanical stress and erosive forces.

-

Ceramic Fiber Textile

It is featured with heat insulation and high temperature protective materials in all kind of thermal installations and heat-conducting systems,widely used in welding,foundry works,aluminum and steel mills,boiler insulation and seal,shipyards,refineries,power plants and chemical plants.

-

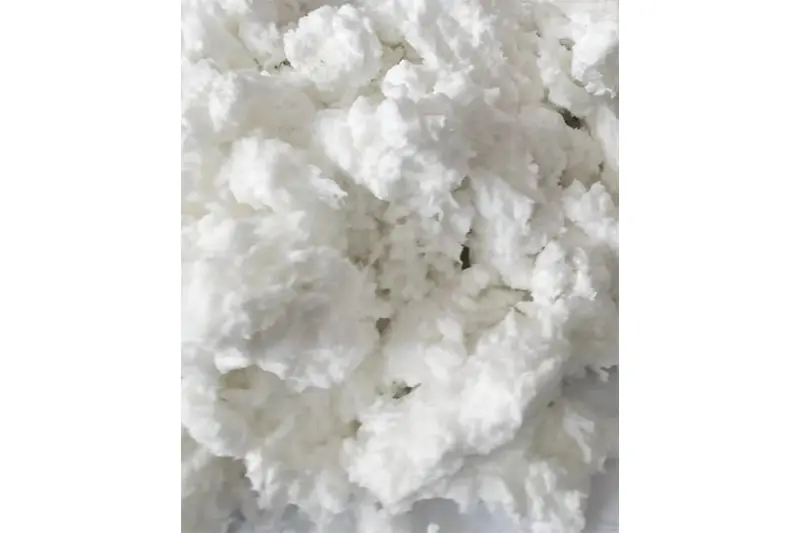

Ceramic Fiber Bulk

Ceramic fiber bulk ,adopting high purity clay clinker, alumina powder and silica powder as material, melted in high temperature by the industrial furnace, blowing or swinging , is produced by swinging technology.

-

Ceramic Fiber Module

CCFR module is made from compressed ceramic fiber blanket. The module is specially designed to meet the thermal insulation requirements of industrial furnaces in some special thermal conditions.

-

Ceramic Fiber Blanket

CCFR blanket is high strength, needled insulating blanket that is made from CCFR bulk. The combination of long spun fibers and needling operation produce tough, resilient and strong blankets, which resist tearing both before and after heating.

-

Ceramic Fiber Vacuum Formed Shapes

Ceramic fiber vacuum formed special shaped products takes high quality ceramic fibers as the main raw materials, then add some organic and inorganic binder, through vacuum forming process, to be made into various shapes high strength ceramic fiber products.

-

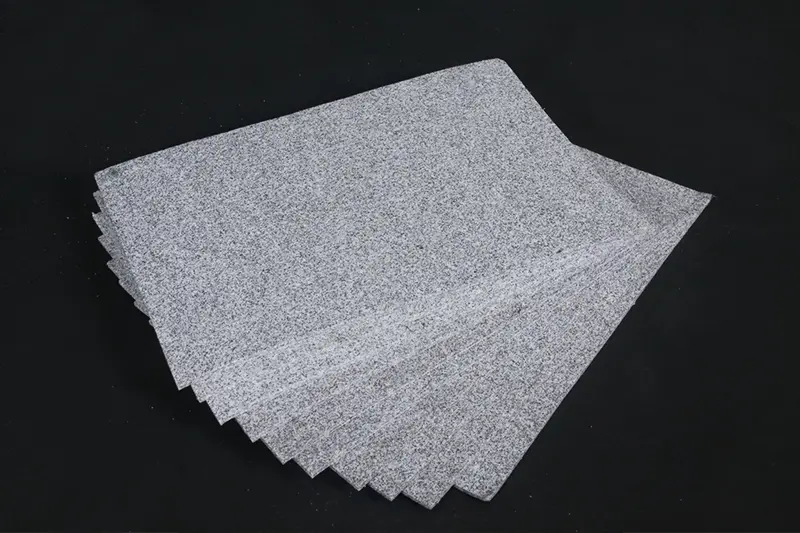

Ceramic Fiber Paper

CCFR® Ceramic fiber paper is manufactured by blending Ceramic Fiber Bulk, binders, and additives.The specialized paper-making process is used to form uniform and flexible paper.

High-Alumina

-

Alumina Lining Brick

It can effectively resist the impact of materials on the pipe wall, protect the equipment from severe wear and corrosion, and extend the service life of the equipment.

-

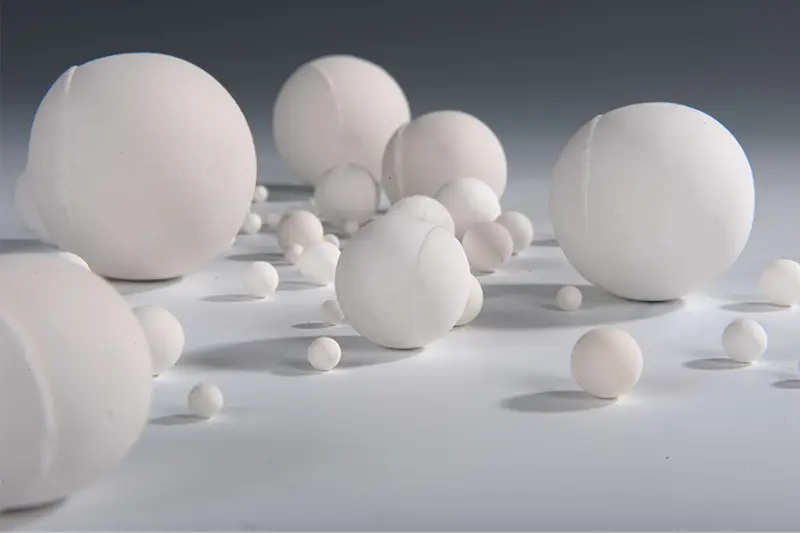

Ceramic Grinding Media

Ceramic grinding media are solid materials used in grinding and milling processes to crush, grind, or refine materials into smaller particles.

-

Ceramic Rollers

Widely used in the manufacturing of wall tile, roof tile, rustic tile, thin tile, porcelain tile, polishing glazed, tableware and other ceramic productions.

Refractory Brick

-

Cast Steel Brick

They were widely used in all parts of fumace lining of metallurgic, petroleum, construction materials, machinery and militaries, etc.

-

Fireclay Bricks

Fireclay bricks are alumina silicate bricks with the refractoriness of SK 32-34 and contain 35- 45% alumina.

-

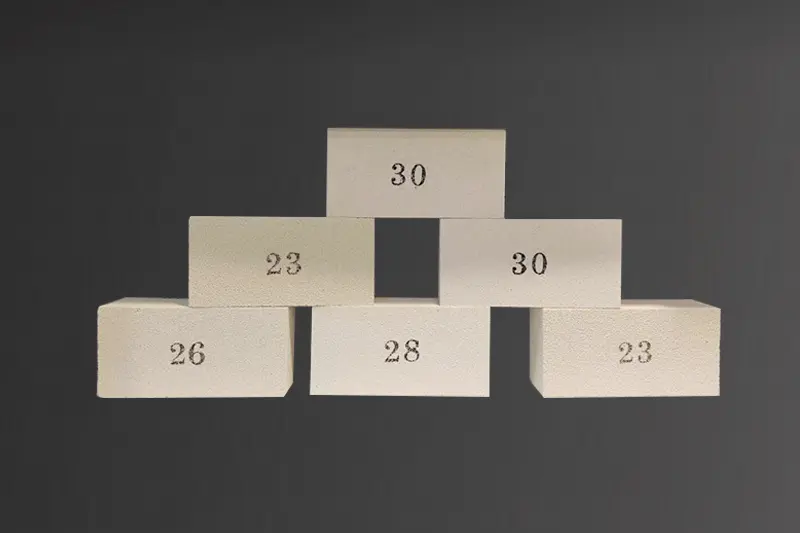

Insulation Brick

CCFR insulation brick is made from high-purity refractory powder and organic fillers which burn out during manufacture to five a uniform and controlled pore sture.

Thermal Insulation Material

Glass Wool

-

Glass Wool Blanket

Glass Wool Blanket is made from natural sand to which recycled glass(cullet) and fluxing agents are added, The material is melted to 1100°C in an electric furnace, and then forced through precision drilled holes in high speed spinning disks, to form fibers.

-

Glass Wool Pipe

Glass Wool Pipe can be used for all kinds of thermal insulation air pipes, oil pipelines, power pipelines and other pipelines, to play the role of thermal insulation, sound absorption and noise reduction, safety and environmental protection, the use of A1 grade uniform slim glass fiber, self-extinguishing from fire, low thermal conductivity.

-

Glass Wool Board

Glass Wool Board can be regarded as porous materials, with good insulation, sound absorption performance.

Rock Wool

-

Rock Wool Blanket

Rock Wool Blanket for industrial insulation is a kind of rock wool product like roll felt, with the sturdy resilient felt and galvanized iron wire netting or stainless steel wire, and the retentivity of this structure makes rock wool felt not break

-

Rock Wool Board

Rock wool board for industry has a certain strength, the fiber structure of which makes itself have the properties of good dimensional stability, thermal stability and chemical stability, and also have another three characteristics of excellent hear resistance, corrosion resistance and low thermal conductivity.

-

Rock Wool Pipe

Rock Wool Pipe is widely used in petroleum, chemical industry, metallurgy, shipbuilding, textile and other industrial boilers and equipment pipe insulation, but also used in the construction industry partition wall, ceiling and internal and external wall insulation and various types of cold, hot pipes and hidden, exposed pipe insulation.

Acoustic Insulating Material

-

Rubber Plastic products

Rubber Plastic products are specialized flexible heat insulating materials that can effectively prevent moisture condensation.

-

Rubber Plastic products

Characterized by low thermal conductivity and high resistance against vapor permeation, these products can reduce end resist vapor permeation in a lung period

-

Rubber Plastic products

By virtue of high-quality raw materials combined with leading production processes, Rubber and Plastic products have excellent heat insulating and fire protection performance.

-

Rubber Plastic products

Rubber Plastic products are specialized flexible heat insulating materials that can effectively prevent moisture condensation.

-

Rubber Plastic products

Characterized by low thermal conductivity and high resistance against vapor permeation, these products can reduce end resist vapor permeation in a lung period

FILL OUT THE

FORM AND

GET FREE

CONSULTATION

You can submit your information online and we will get back to you within 24 hours!

Address:NO. 203 Zhongxin Road, Zhangdian, Zibo, Shandong, China