Welcome to SHANDONG HIKING INTERNATIONAL COMMERCE GROUP CO.LTD !

COPYRIGHT © 2018 SHANDONG HIKING INTERNATIONAL COMMERCE GROUP CO.LTD 鲁ICP备18023600号

Multi Module

Multi Module

Descriptions

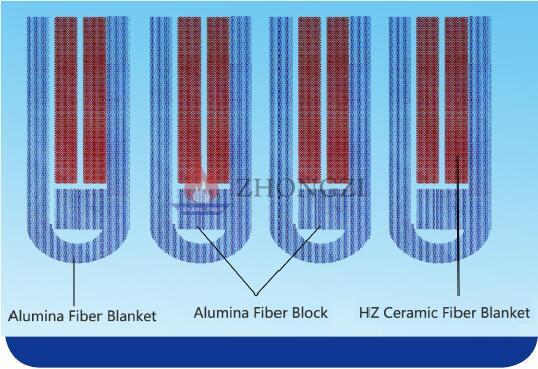

Alumina Fiber Composite Module is a type of refractory fiber composite member, which is manufactured through cutting, compositing, folding, compressing and extruding by Alumina fiber blanket and HZ ceramic fiber blanket according to a certain size.

Product Category

Alumina Fiber Composite Module LYLX-1500FM1

Alumina Fiber Composite Module LYLX-1500FM2

Alumina Fiber Composite Module LYLX-1500FM3

Alumina Fiber Composite Module LYLX-1550FM

Alumina Fiber Composite Module LYLX-1600FM

Features

High temperature resistance:can used for 1250℃~1500℃ high temperature furnace all fiber lining

High temperature stability:all alumina fiber blanket on the hot face, no devitrification and pulverization in high temperature,low shrinkage on heating,long service life

Low heat storage:Energy Saving Effect Obviously to the Punctuated operation heating furnace

Low thermal conductivity

High thermal shock resistance

Excellent high temperature air Erosion performance resistance,the highest air speed can be 50m/s

Chemcial Properties Stability、strong erosion resistance performance

Easy operation,short construction period

High cost performance:variety structure types, flexible composite types

Typical Applications

Metallurgy industry 1250℃~1500℃ furnace lining

—Furnace lining for Pallet car forging furnace、walking beam type furnace、circular furnace、Slab slab continuous casting and rolling reheating furnace、Continuous annealing galvanizing line(Without oxidation furnace heating section)、Silicon steel even back line、Stainless steel even back lines

—Walking beam furnace discharging furnace door lining

—Heating furnace diaphragm wall module

High temperature heating furnace lining in Petrochemical industry

—Ethylene cracking furnace stand column and corner lining

—Reformer lining

—All fiber lightweight Observation Port

Fast firing kiln lining in Ceramic industry

Shuttle kiln lining in Electromagnetic industry

Heating furnace burner

Typical Parameters

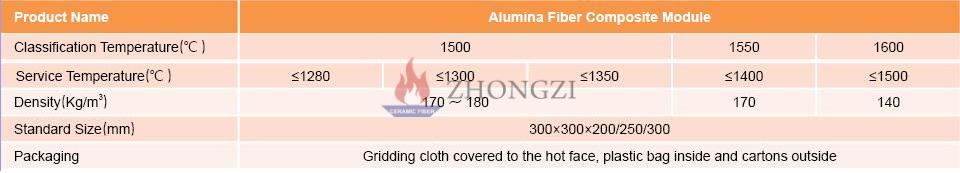

•Index of Alumina Fiber Composite Module

•Index of HZ Ceramic Fiber blanket

|

Product Name |

HZ Ceramic Fiber blanket |

|

|

Classification Temperature (℃) |

1400 |

|

|

Chemical Composition |

ZrO2(%) |

14~16 |

|

Al2O3+ SiO2+ ZrO2(%) |

≥99 |

|

|

Fe2O3(%) |

≤0.2 |

|

|

K2O+Na20(%) |

≤0.2 |

|

|

Density(Kg/m3) |

96 |

|

|

Fiber Diameter(μm) |

3~5 |

|

|

Shot content(%)(φ≥0.212mm) |

≤15 |

|

|

Tensile Strength(MPa)(Thickness25mm) |

≥0.04 |

|

|

Thermal Conductivity(W/m.k)(500℃) |

≤0.153 |

|

|

Shrinkage on Heating(%)(1350℃×24h) |

≤-3 |

|

|

Dimension(mm) |

7200×610×12.5/25 |

|

The data shown are average results of tests under standard procedures and are subject to variation. Results should not be used for specification purposes or creating any contractual obligation. For more information on the safety application or materials, please refer to the work practices and material safety data sheet.